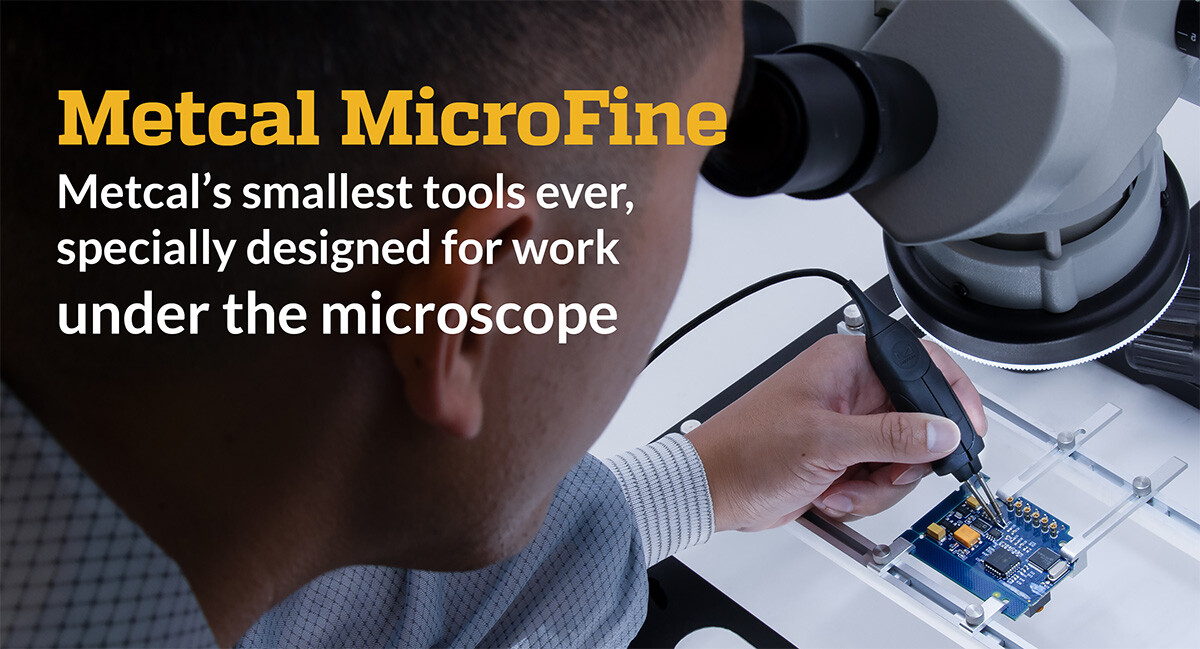

METCAL™, a leader in benchtop soldering and fume extraction systems, announces the release of their new MicroFine soldering handpieces and cartridge tips for use under the microscope..

Metcal Introduces New MicroFine Products for Soldering Under the Microscope

By Metcal Marketing on Oct 24, 2024 5:26:03 PM

Why Metcal is Offering Adjustable Temperature Soldering Now

By Curtis Yamauchi on May 26, 2020 9:42:57 AM

We know what you are asking yourself!!!

Evaluating Performance for Adjustable Soldering Systems

By Curtis Yamauchi on May 15, 2020 6:17:02 PM

When looking at performance for hand soldering in electronics manufacturing, Operations Engineers need to be very focused on three key metrics: time to temperature, dwell time and thermal recovery. These three metrics together will identify the best soldering product for the production line and will help maximize throughput and lower scrap in the process.

IPC-CFX Process Control and Traceability: Real Time Risk Mitigation in Hand Soldering Applications

By Hoa Nguyen, CTO, OK International, and Ed Zamborsky, Regional Sales Manager, Metcal on May 28, 2019 6:00:00 AM

This article was originally published in the May, 2019 issue of U.S. Tech and can also be found online at US-Tech.com.

Metcal Introduces the New CV-500 Connection Validation™ Soldering System

By Metcal Marketing on Dec 11, 2018 12:04:22 PM

CYPRESS, Calif., Dec. 10, 2018 – Metcal, part of OK International and Dover (NYSE: DOV), is pleased to introduce the new CV-500 Connection Validation™ Soldering System, the companion station to the CV-5210 CV Soldering System. The CV-500 packs all of the Connection Validation (“CV”) technology into a compact, economical housing.

Metcal Receives Best of Industry Award for Hand Soldering

By Metcal Marketing on Nov 6, 2018 5:00:00 AM

CYPRESS, CA ― November 2018 ― Metcal is pleased to announce that it was awarded a 2018 Best of Industry Award from EM Media. The awards bring together industry leaders to celebrate excellence and leadership. Metcal received the Best Hand Soldering Award.

Metcal's Hoa Nguyen to Speak at i4.0 Connect Forum

By Metcal Marketing on Nov 2, 2018 9:51:47 AM

Hoa Nguyen, Metcal’s Chief Technology Officer will be speaking at the i4.0 Connect Forum, November 6th, in Silicon Valley. Mr. Nguyen will be speaking about IPC CFX Process Control and Traceability for Metcal's Real Time Risk Mitigation in Hand Soldering Application.

Check out the latest Metcal Soldering and Rework Technology at SMTAI

By Metcal Marketing on Sep 20, 2018 11:20:04 AM

CYPRESS, CA ― September 2018 ― Metcal announced plans to exhibit at SMTA International, scheduled to take place Oct. 16-17, 2018 at the Donald Stephens Convention Center in Rosemont, IL. The company will demonstrate its Connection Validation (CV) Soldering System with new hand-pieces, MX-5270 system with solder wire feeder, Digital Hot Air Pencil, Solder Tip Cleaner and VFX-1000H Volume Fume Extraction System in Booth #330.

5 Ways Process Engineers Build A More Productive Team

By Metcal Marketing on Aug 21, 2018 12:00:55 PM

9 Tips to Extend the Life of Your Soldering Iron

By Metcal Marketing on Jul 26, 2018 9:00:00 AM

A soldering iron is an invaluable tool when it comes to hand soldering tasks. But even the best soldering station will eventually fail if it is not used correctly. We have provided helpful advice for your soldering iron tips before, but here are nine tips that will help keep your soldering iron itself working for years to come.

5 Tips for Solder Tip Selection

By Metcal Marketing on Jun 21, 2018 1:38:18 PM

There are many different soldering tip designs to choose from when selecting or updating an iron. The different shapes have their own advantages, and some are most effective when used for a given application. Let's look at the most common types of solder tip designs and some solder tip basics.

The Clear Advantages of a Smart Soldering Station

By Metcal Marketing on Jun 12, 2018 1:10:00 PM

Soldering irons have been in use for a very long time, and they do the same job today as they did in the past - they make the electrical connection between components through the use of melted solder. But just as the components have become far more advanced, the soldering iron has progressed as well. This is why you should be using a smart soldering station for your electronic work.

How Will the Computerization of Manufacturing Affect Your Business Model?

By Metcal Marketing on Jun 7, 2018 9:00:00 AM

Technology in manufacturing continues unabated in its evolution, something perhaps sounding daunting, though also helping many of your workers. With the prevailing thought that computers and robots are going to replace manufacturing jobs, much of this is proving false. As TIME Magazine details, digital technologies ultimately help complement workers in the manufacturing sector.

The Four Principles of Today's Industry 4.0

By Metcal Marketing on May 30, 2018 1:01:25 PM

The trend known as Industry 4.0 is an amalgamation of technologies that have only relatively recently came into being. It is made up of cyber-physical systems, cloud computing, and cognitive-based processing, along with advanced computing paradigms. With its revolutionary impact on the world of manufacturing, it is often referred to as the fourth industrial revolution. Industry 4.0 is leading the way for tomorrow's manufacturing base, and it is defining the construction of Smart Factories.

OK International Wins the Dover Safety Excellence Award

By Metcal Marketing on May 24, 2018 8:00:00 AM

INAUGURAL WINNER OF THE DOVER SAFETY EXCELLENCE AWARD

Cypress, California, May 23, 2018 – Dover Corporation today presented the 2017 Dover Safety Excellence Award to the OK International facility in Cypress, California. The award was based on both quantitative and qualitative measures for outstanding safety performance and exemplary employee participation in safety programs. OK International, a Dover Company, received the Gold Award for the small site category (under 150 employees). Overall, 29 locations world-wide were nominated with 7 locations ultimately receiving an award. Andy Fincher, President, Dover Engineered Systems, presented the award today at the Cypress facility during an all employee event.

How to Remove Oxidation from Your Solder Tips

By Metcal Marketing on May 22, 2018 8:00:00 AM

A soldering iron can be an indispensable tool for electronics use. A new or adequately cared for soldering iron is very efficient in its operation, allowing components to be quickly and easily soldered into place. But sometimes the soldering tip gets a buildup of oxidation on its surface. When this happens, the soldering iron no longer functions as it should. But with a little effort, the tool can be restored to complete functionality. Let's take a look at soldering tips and how to deal with oxidation.

5 Ways to Extend the Life of Your Solder Tips

By Metcal Marketing on May 15, 2018 9:07:29 AM

When it comes to hand soldering tasks, the correct soldering iron is the best tool in your toolbox. Properly cleaned and cared for, a soldering iron can provide many hours of dependable service. The solder tip is the business end of a soldering iron, and it acts as the heat transfer component that melts the solder and heats the work, allowing everything to meld. For maximum life and continued efficiency, a solder tip should be adequately cared for and maintained. Here are some tips for getting the most out of your solder tips and cartridges.

Metcal's APR Product Line Acquired by Desco

By Metcal Marketing on Apr 19, 2018 5:12:06 PM

January, 2018

Metcal Wins Global Technology Award for Connection Validation

By Metcal Marketing on Nov 14, 2017 2:00:00 PM

Metcal was presented with a 5th international award for the groundbreaking Connection Validation technology at productronica 2017, in Munich, Germany. We were awarded a 2017 Global Technology Award in the category of Hand Soldering for our CV-5200 Soldering and Rework Systems with Connection Validation technology. The award was presented at a Tuesday, Nov. 14, 2017 ceremony by Global SMT magazine.

Solder Joint Panel with SMT Magazine

By Robert Roush on Oct 31, 2017 7:25:21 AM

Our own Robert Roush recently joined a panel on the challenges of proper solder joints with Indium Corporation’s Brook Sandy-Smith, technical support engineer, Andrew Nunenkamp, director of engineering at MC Assembly, and Vince Burns, quality engineer and an IPC Certified Trainer.

Protect your Solder Tip Investment - Introducing Metcal Solder Tip Cleaner

By Metcal Marketing on Oct 26, 2017 12:07:00 AM

Solder tips represent a major part of the total cost of ownership for a soldering system. Your operator's choice of tip, use of a solder sleeper stand, and the method and frequency of tip cleaning and replacement all can play a part in your solder tip consumable costs.

productronica 2017 Lineup Announced!

By Metcal Marketing on Oct 19, 2017 10:24:43 AM

We're excited to be exhibiting at productronica 2017! We'll be at Hall A2, Stand 135, Nov. 14 – 17, 2017 at the Messe München in Germany. We'll be showing the brand new Connection Validation (CV) Selective Soldering System at the show for the first time, along with a range of our new soldering tools. See below for the whole lineup!

Introducing our Digital Hot Air Pencil - HCT2-200

By Metcal Marketing on Oct 13, 2017 12:06:00 AM

As component miniaturization continues, assembly experts need to access and rework components on the board without affecting adjacent parts. Traditional handheld convection systems can accidentally reflow or dislodge adjacent components that may require additional rework, or even scrap.

How Connection Validation Works

By Robert Roush on Oct 10, 2017 10:51:05 AM

Metcal's exciting and innovative Connection Validation product has been a big hit, winning four awards to date. We've received questions from around the world, looking for a little more detail about how the process works. The infographic below helps explain.

New Products Highlighted at SMTAI 2017

By Metcal Marketing on Sep 24, 2017 9:32:56 PM

We had a great show at SMTAI in the Chicago area last week. Hopefully many of you got to come by and visit. We had a number of industry luminaries drop by the booth, and we had a lot of folks come by during the Tech Tours.

Metcal Wins EM Best of Industry Award

By Metcal Marketing on Sep 18, 2017 3:27:04 PM

Electronics Maker, a leading electronics magazine announced the winners today of the third edition of the EM Best of Industry Awards. We are excited to announce YET ANOTHER award - we won ‘Best Soldering and Rework Solutions’ Award.

How Metcal's NEW Solder Tip Temperature Display Works

By Robert Roush on Sep 8, 2017 2:06:13 PM

Until the release of our CV-5210 power station, Metcal soldering stations have not featured a tip temperature display. Many customers, especially Contract Manufacturers have lamented this, because of their need to provide documentation and support for their customers and ISO or other process control requirements.

We’re Exhibiting at SMTA International 2017!

By Metcal Marketing on Sep 1, 2017 9:00:00 AM

Read our press release about plans to exhibit at SMTA International, scheduled to take place Sept. 19-20, 2017 at the Donald Stephens Convention Center in Rosemont, IL. We'll be at booth #208. Come see us!

The Health Risks of Solder Flux Fumes

By Metcal Marketing on Aug 21, 2017 7:00:00 AM

The dynamic, high-growth nature of the electronics industry requires that manufacturers achieve higher standards of quality and efficiency in production to maintain a competitive edge. Though sometimes overlooked, a critical need in attaining a high level of manufacturing productivity is the creation of a comfortable, pleasant work environment with worker health and safety as a top priority.

On Solder Tip Cost and Life

By Ed Zamborsky on Aug 14, 2017 11:17:18 AM

Let’s face it soldering tips and cartridges cost money. And when you combine that with operators forced to solder at 850°F or higher to keep up to speed, those tips are breaking down and costing you a bunch of dollars.

Internet of Things - a Primer

By Hoa Nguyen on Aug 7, 2017 12:38:48 PM

Hoa Nguyen, Metcal's CTO recently attended the IoT Evolution Expo, a meeting of the world's IoT experts. We asked him to tell us what he learned. Thankfully, Hoa helps us out by starting with the basics.

Introducing Midwest Regional Sales Manager, Kit Weste

By Metcal Marketing on Aug 4, 2017 7:02:00 AM

Kit joined Metcal in 2006 as a Technical Service Engineer, focused on providing application support, machine installs and training, and technical service to customers around the world, traveling throughout North America as well as South America and Asia. In 2013 Kit was promoted to Technical Service Manager, overseeing the Technical Service Department and Repair Department, with a strong focus on Quality Assurance and Control.

How SmartHeat Technology Works: A Tutorial

By Ed Zamborsky on Aug 3, 2017 2:11:15 PM

We often get detailed questions from Process Engineers about how SmartHeat really works, and whether fixed (or stable) head soldering stations or variable heat is what they need. Our expert, MetcalMan Ed Zamborsky himself has written this article about Metcal's SmartHeat first, to talk about how stable temperature soldering really works!

Introducing High Thermal Demand Upgrade Kit

By Metcal Marketing on Jul 27, 2017 6:38:54 AM

Turn your Metcal MX-Series soldering station into a powerhouse! Have some applications where your current tips and handpieces are not getting the job done? Maybe it's a really thick board, or maybe some other type of heavy thermal demand connection.

That's why we've recently released the new High Thermal Demand Hand Piece. If you're having to turn to up the heat to dangerous levels, or spend extra time over a pre-heater, grab the new RED iron from Metcal. Your operators will love the ergonomic, lightweight handpiece, improved power transfer, and the temperature control your Metcal MX-Series soldering station provides.

Removing Solder and Adhesive without Damaging PCB Component Pads!

By Metcal Marketing on Jul 26, 2017 9:48:11 AM

If you have a bunch of complicated boards that need rework, and you need to remove solder and adhesive, it's a time consuming and risky application. In fact, even the most experienced and technical operators can get into delicate situations when faced with repeating component and pad cleaning over and over.

Connection Validation Monitor Software Now Available

By Metcal Marketing on Jun 29, 2017 2:43:32 PM

The hugely popular Metcal CV-5210 is now available through select Distributors. We've heard from many industry leaders about the importance of traceability. Contract Manufacturer customers are raving about Connection Validation's use in promoting themselves and their quality control programs.

Introducing Rick Nuttall, Director European Sales

By Metcal Marketing on Jun 23, 2017 4:57:13 PM

Rick Nuttall is a force to be reckoned with in OK International's European office. Aside from serving as Sales and Marketing leader for Metcal, Rick is responsible for the other OK International brands, Techcon Systems, Quant3D and ProWorks.

Introducing the new VFX-1000 Volume Fume Extraction System

By Metcal Marketing on Jun 20, 2017 2:13:11 PM

Solder flux fumes generated during the soldering process can create health hazards in your workplace. Since employee health is a key responsibility of any operation, and in many countries solder fume capture is a legal requirement, many electronics manufacturing facilities are moving to benchtop or under-bench fume extraction systems.

Meet Metcal Eastern RSM Ed Zamborsky

By Metcal Marketing on Jun 9, 2017 8:49:00 AM

Ed Zamborsky is Metcal's Eastern Regional Sales Manager, as well as a Master Applications Engineer. Ed visits customers throughout North and South America helping them evaluate new and complicated PCB assembly and other difficult applications.

Solder Tip Care Infographic: Do's and Don'ts

By Metcal Marketing on Jun 2, 2017 4:51:44 PM

If you take good care of your soldering tips, they'll take care of you and improve your return on investment. Download this handy solder tip care infographic.

Connection Validation Wins SMT China Vision Award

By Metcal Marketing on Jun 1, 2017 5:05:00 PM

We are very excited to have received a 2017 SMT China Vision Award in the category of Hand Soldering for the CV-5200 Connection Validation™ Soldering Station. The award was presented to the company on April 25, 2017 at the Shanghai World Expo Exhibition & Convention Center during NEPCON China. This is the second award that the company has received for Connection Validation since its introduction in early 2017.

Why Metcal Soldering Irons Don't Need Calibration

By Metcal Marketing on May 26, 2017 12:15:49 PM

One of the questions we're frequently asked is "why don't Metcal soldering irons require calibration." In fact, there are a number of soldering stations that no longer require calibration, partly because the IPC standards have changed.

Traditionally, a conventional soldering station uses a temperature measuring sensor that feeds back the heating element temperature (not the tip temperature.) In many systems, the temperature that is displayed is somewhere between the tip (working surface) and the heater, and then is fed back to the temperature control PCB. These temperature sensors can and do vary over time. This variance can cause the displayed temperature to be different from the measured tip temperature.

Meet Chief Technology Officer Hoa Nguyen!

By Metcal Marketing on May 19, 2017 12:28:12 PM

While Hoa has been with OK International for years, he's been driving the many new innovations you're seeing in 2017 and beyond. It seems like a great time for Metcal fans to learn more about him!

Trifecta! CV Wins EM Asia Innovation Award for Hand Soldering Tools

By Metcal Marketing on Apr 26, 2017 11:18:51 AM

Today Metcal was awarded the third award for the CV-5200 Connection Validation™ Soldering Station.

Metcal’s Scarab Site Cleaning System – Check Out the 2-Minute Video

By Metcal Marketing on Apr 3, 2017 11:00:00 AM

Contactless solder cleaning is rapidly replacing manual cleaning methods in more and more rework applications. Metcal’s Scarab system provides an easy to use and cost effective solution for PCB cleaning challenges faced by most rework manufacturers today.

Paired on a bench top with the Metcal Scorpion Advanced Package Rework System, any rework operation can now effectively and economically clean a board and also ensure accurate component placement and custom tailored reflow profiles in a single bench top operation.

Metcal's New Solder Wire Feeder - Check Out the 2-Minute Video

By Metcal Marketing on Mar 27, 2017 5:04:19 PM

Metcal’s Solder Wire Feeder adds control and convenience to the soldering process. With digital controls, high performance, and its ability to handle multiple solder wire diameters, it provides repeatability and functionality to any hand soldering process. The Solder Wire Feeder pairs with Metcal’s MX-5200 series or MX-500 Soldering and Rework Stations.

Metcal Brings Big Science and High Reliability to Hand Soldering

By Metcal Marketing on Mar 13, 2017 9:10:18 AM

Recently, SMT Magazine caught up with Metcal Product Support Engineer, Robert Roush to discuss Metcal’s new patented Connection Validation Hand Soldering System. The discussion gets into how originally with the introduction of SmartHeat, Metcal allowed customers to achieve a new level of process control in their hand soldering operation and how with Connection Validation, Metcal is taking process control into greater heights.

Metcal President, Chris Larocca Discusses New Products at APEX (Video)

By Metcal Marketing on Mar 9, 2017 1:03:17 PM

Christopher Larocca describes Connection Validation (CV), the latest Metcal innovation in hand soldering. CV provides close loop feedback to the operator via a LED ring integral to the hand-piece that detects successful intermetallic compound (IMC) formation - resulting in more reliable solder joints.

Observations from IPC APEX 2017 - TURN TOWARD THE FUTURE

By Metcal Marketing on Feb 22, 2017 8:27:47 AM

Chris Larocca at APEX 2017

By Metcal Marketing on Feb 17, 2017 2:41:00 PM

Metcal Wins NPI Award for Best Hand Soldering Product

By Metcal Marketing on Feb 14, 2017 7:25:00 PM

We're excited to announce we have been awarded a 2017 NPI Award in the category of Soldering – Hand Tools for CV-5200 Connection Validation™ Soldering Station!,

The Circuits Assembly NPI Awards are chosen by an independent panel of practicing industry engineers. Evaluation of the award entries is based on several criteria, including innovation; compatibility with existing technology; cost-effectiveness; design, and more. The award was presented to the company during a Tuesday, Feb. 14, 2017 ceremony that took place at the San Diego Convention Center during the IPC APEX EXPO.

The patented CV-5200 Connection Validation™ Soldering Station is the next major step in the evolution of process control. CV is the world’s first soldering station capable of evaluating the quality of the solder joint by calculating the intermetallic compound formation and providing real-time, closed-loop feedback to the operator via an integrated LED ring in the hand piece.

“Connection Validation sets the stage for a major advancement in machine intelligence,” according to Christopher Larocca, President of OK International, which acquired Metcal in 1996. “It fundamentally mitigates the risk of product failures, imperiled user safety, recalls, and unrecoverable cost – which can result in significant damage to a company and its brand. Manufacturers can now confidently develop faster, more advanced products, while boosting performance and cost efficiency,” added Larocca.

The CV-5200 features a Chip-in-Cartridge technology that precisely calculates and displays tip temperature on the unit’s color TFT graphic display. With the CV-5200’s communication port, tip temperature and other data can be collected and analyzed in production reports.

Premiering in 2008, the NPI Awards program is an annual celebration of product excellence in electronics surface mount assembly. Premier products based on the finest examples of creative advancement in technology are chosen by a distinguished panel of electronics assembly industry experts.

Metcal Introduces the Next Big Step in Process Control: Connection Validation™

By Metcal Marketing on Feb 13, 2017 3:05:00 AM

Metcal’s CV-5200 Connection Validation™ Soldering Station provides real-time closed loop feedback on intermetallic compound formation— the world’s first. Plus, a new communication port enables process traceability and firmware upgrades.

Metcal Team to Present on Rework and Risk Mitigation at IPC APEX 2017

By Metcal Marketing on Feb 8, 2017 6:29:51 PM

Metcal will be presenting two white papers at IPC APEX 2017 in San Diego this February 14-16. Take a look at a summary of what our engineers will be presenting:

When: Wednesday, Feb. 15th, 1:30 -3:00 PM

What: Panel: S17: Rework I

Location: 1A

Rework Challenges for Leading Edge Components BGA, QFN and LED in Today’s Fast Moving Industry

(see also below: Risk Mitigation in Hand Soldering)

Presented by Paul Wood, Metcal Advanced Product Applications Manager

The electronics assembly industry continues to face the challenges associated with BGA, QFN, and LED packages. The demand for more performance by consumers drives change, which results in greater component density. Component density on printed circuit boards continues to decrease with a corresponding increase in component complexity and reduction in pitches. Good examples of these industrial trends are smart phones, tablets and wearables.

Metcal Announces Major Rebranding on Milestone 35th Anniversary

By Metcal Marketing on Jan 31, 2017 4:47:00 PM

CYPRESS, CA― February 1, 2017 ― With the upcoming introduction of a game-changing technology, new investments in technology and engineering, and a deep product pipeline, Metcal announces a revitalization of its brand and further strengthens its position as the industry innovator.

We Are Metcal! Check out our Brand Video

By Metcal Marketing on Jan 31, 2017 4:46:35 PM

Industry Trends Making Manual PCB Cleaning Increasingly More Challenging

By Metcal Marketing on Oct 27, 2016 1:30:07 PM

In addition to PCBs becoming thicker over the years, pad and pitch size have also reduced significantly, with many smartphones and other devices now utilizing pad sizes as small as .25mm millimeters spaced at intervals of .5mm. It is known in the industry that new chips are scheduled for release in the next two to three years that utilize designs calling for pad sizes as small as .15 mm with a .3 mm pitch. With adjacent parts so close together, avoiding hitting them with the wick during manual cleaning—and creating another round of rework—will most likely become impossible for even the most skilled technician.

Further, traditional cleaning methods can be even less effective when it comes to cleaning PCBs incorporating advanced chip technologies. For example, one new technology is providing outstanding improvements in security, making it nearly impossible for criminals to access data stored on the processor. However, due to factors such as differing size pads and uneven solder volumes, manual cleaning can be a significant challenge.

Another technology, Ceramic Ball Grid Array (CBGA), a specialty process used in aerospace, military and other high reliability applications, is another high value case in point. These boards,

Traditional Manual Cleaning Processes Can Damage PCBs

By Metcal Marketing on Oct 24, 2016 2:01:33 PM

That’s why Contactless Solder Cleaning is rapidly replacing manual cleaning in increasingly more rework applications.

The PCB rework process has long consisted of three steps:

- Removal of the inoperative component.

- Cleaning of residual solder from the ball grid assembly (BGA) pads which held the inoperative component in place.

- Replacement with a new component to create a viable PCB.

The first and third steps—removal and replacement—have long been automated, and are completed on rework machines with operator assistance. Cleaning, the middle step—and arguably, the most sensitive and vital step when it comes to reclaiming a damaged board—is often done completely manually by a skilled and experienced technician. The cleaning is performed with hand tools, usually a wicking braid and a soldering iron, using standard or specialized tips. The effectiveness of the operation is highly dependent on the skills of the individual operator. With the emphasis often placed on work throughput, board damage is quite common.

One common scenario in manual cleaning is the destruction of a pad due to sticking, when the heat of the soldering iron momentarily dissipates through the board, causing the delicate pad to stick to the wick and be chipped or lifted off the board entirely when the operator pulls the tool back. Overwhelming, destruction to a pad results in a wasted, scrap board.

Contactless solder cleaning is rapidly replacing manual cleaning in more and more PCB rework applications

By Metcal Marketing on Oct 18, 2016 5:44:37 PM

Today's manufacturers of printed circuit boards (PCBs) are strongly quality driven, but even among those operations that are able to drive yields near or even above 99%, the huge volumes associated with applications such as smartphones and tablets could still leave them with thousands of boards per week that come off the assembly line damaged and in need of rework.

Since the cost of these PCBs can be well over US$200 each, most manufacturers and OEMs consider it vital to develop an effective process for working to reclaim these boards and minimize scrap PCBs—and the resulting losses—in their operations.

(Off center solder ball in the corners)

Metcal's Scarab PCB Contactless Desoldering Product Featured at SMTAI

By Metcal Marketing on Oct 5, 2016 5:32:28 PM

In case you missed our booth at the SMTA International trade show in Chicago last week, we didn’t want you to miss our Sr. Application guru, Paul Wood’s interview with I-Connect007 regarding Metcal’s new PCB contactless desoldering and cleaning product.

Metcal’s award-winning Scarab Cleaning System is a cost effective solution to PCB cleaning challenges faced by today’s rework manufacturers. The standalone product can easily be added to a current rework system, enabling a single operator to manage a cleaning and rework assembly line, reducing labor costs and increasing throughput.

Click on the video for Paul's interview!

Metcal Application Manager Paul Wood Attend SMTAI Rework Panel Expert

By Metcal Marketing on Sep 23, 2016 5:23:49 PM

Metcal has announced that Paul Wood, Advanced Product Applications Manager, will participate in an expert panel conducted by Global SMT & Packaging Magazine during SMTA International. The panel, entitled, “Rework and Repair – Challenges,” is scheduled to take place Wednesday September 28, 2016.

Reworking PCB assemblies is becoming increasingly challenging. This expert panel will discuss some of the techniques and processes for dealing with:

|

Mr. Wood is an industry expert in the BGA/CSP/Array package rework arena. With 34 years of service at OK International, Inc., and 43 years’ experience in the electronics industry, Mr. Wood has used his global experience in rework to keep electronic assembly manufacturers on the leading-edge of technology.

Welcome New RSM Gabriel Ortiz to Metcal!

By Metcal Marketing on Sep 20, 2016 4:46:21 PM

We're very excited to introduce the newest Regional Sales Manager for Metcal, Gabriel Ortiz.

Why You Should Use a Soldering Sleeper Stand

By Robert Roush on Sep 20, 2016 2:27:31 PM

Solder tip life is a constant discussion among users of hand soldering for almost all applications. Whether you're in production, rework, or R&D, the cost of tips and their longevity impacts the ROI of your overall soldering investment. While operators almost always want the tip to be hot, hot, hot, and all the time, using a soldering iron sleep stand can significantly improve the life of your solder tips.

When used when the handpiece is idle, a Solder Sleep Stand automatically reduces the power supplied to the hand piece, leading to:

- Reduced idle temperatures

- Slower chemical reactions

- Less inter-metallic formation

- Less de-wetting

- Longer tip life

Take a look at this chart that illustrates the effect of using the sleeper stand for just a few minutes.

You can see how this can significantly reduce the power consumption as well, meaning for a production environment, it can affect your total ROI.

Theoretical Example:

If you have 5 soldering irons each in production using on average 40 watts per hour over an 8 hours day your consumption is: